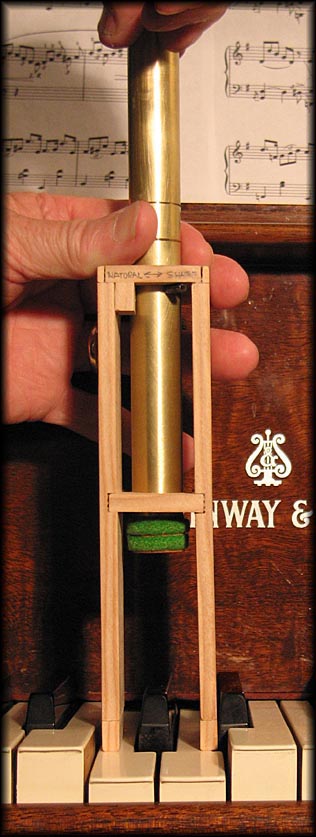

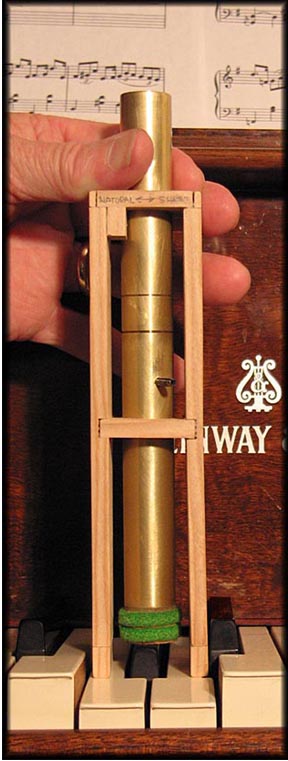

Here's a sketch which illustrates how the thumper works. When the yellow brass rod is in its down position (roll pin resting on lower guide), about an inch of rod protrudes above the upper guide -- sufficient for a finger grip. The roll pin (black dot) limits rod travel when the rod is drawn up for a test blow. The red rectangle is a stop block which stops the roll pin when the rod is drawn up for naturals. For sharps, the rod is rotated so that the roll pin misses the block -- and stops against the upper guide.

|

|

|

|---|---|---|

Double pad: medium-firm leather with Steinway punchings. The double-pad delivers a dead blow (no rebound).

|

|

|

Notice the roll-pin (arrow) is under the stop block in the left picture, while in the right picture the rod has been rotated so that the roll pin misses the stop block. The two rotation positions of the rod determine whether the test-blow will be for a natural, or for a sharp. [Ignore the scribed rings in the rod -- this is a prototype which was used to try many ideas!]

|

|

|

THUMPER POSITIONED FOR A NATURAL left picture: The cage centers the rod by straddling the key. Pressing down on the cage establishes the reference height for the test blow on the natural. Note that the roll pin (arrow) is rotated so that it stops underneath the stop block; this sets the correct test-blow distance for the natural. right picture: A 2-inch drop delivers a substantial blow.

|

|

|

THUMPER POSITIONED FOR A SHARP left picture: The cage fits nicely between the keys as shown, and when the naturals are depressed, establishes the reference height for the test blow on the sharp. The pin is rotated so that it passes the stop block and stops underneath the guide; this sets the correct test-blow distance for the sharp. right picture: Sharp test blow completed. |

|

|